Ferrules & Nuts

We manufacture high quality crimped ferrules for hydraulic hoses.

Ferrules are also called as Sleeves / Shells / Caps / Boccola / Press Hulse / Casquillo. Ferrules play a very important role as they are a medium to join the end fittings to the Hydraulic hose. Even under high pressures these ferrules keep the relation of end fitting and hose intact. Hence it can be called as safety critical part. Internal profile of the ferrule is the gimmick of this part. Design has to be done carefully while keeping performance in mind.

Feautures of our Ferrules :

Correct use of raw materials – Raw materials which have good malleable (flowing) property result in effective crimping and good holding properties. We use SAE 1010/SAE 1018 as raw material

Correct heat treatment – Annealing

Surface treatment – Zinc trivalent (Cr6 free) coating

Cost effective

High quality

For good volumes we adopt cold forging & machining route. Advantages of this method:

Ferrule gets grain flow and homogeneity

Crack problem completely vanishes

Ferrule becomes a lot stronger

For small volumes we opt for bar route but at the same time we carry out crack detection test at bar level (in-house) and also carry out heat treatment process to get its crimping quality.

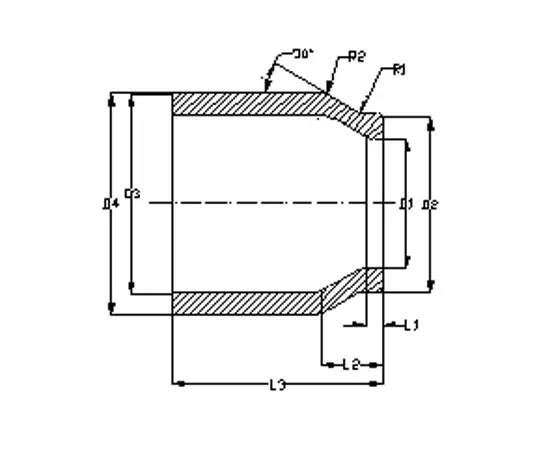

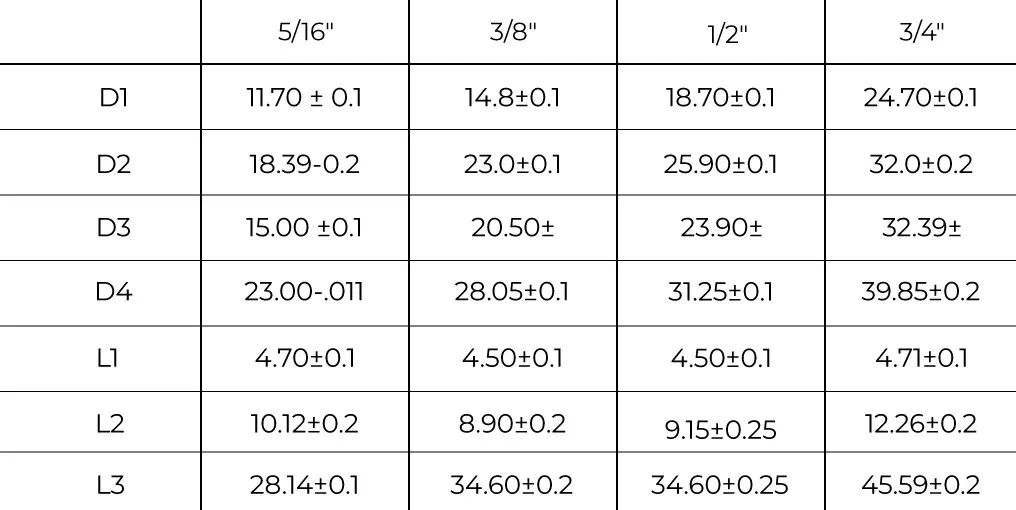

R1T-R2T Ferrules

Shell

Shell

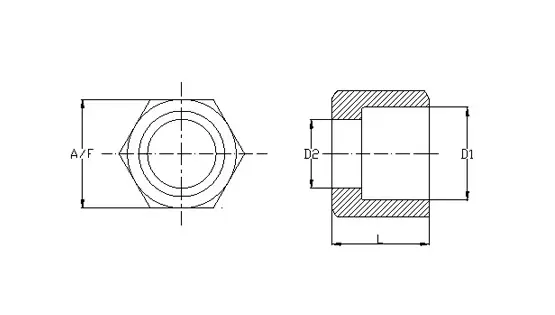

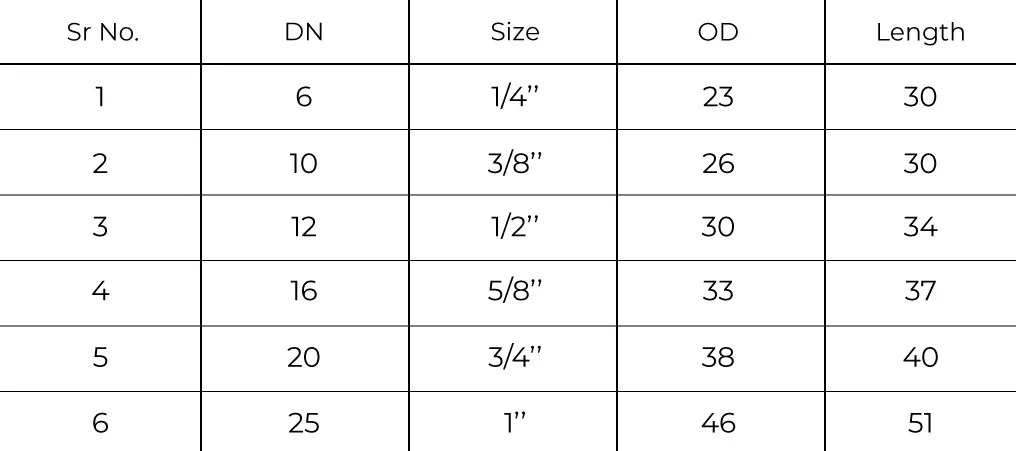

Cold Forged NUT

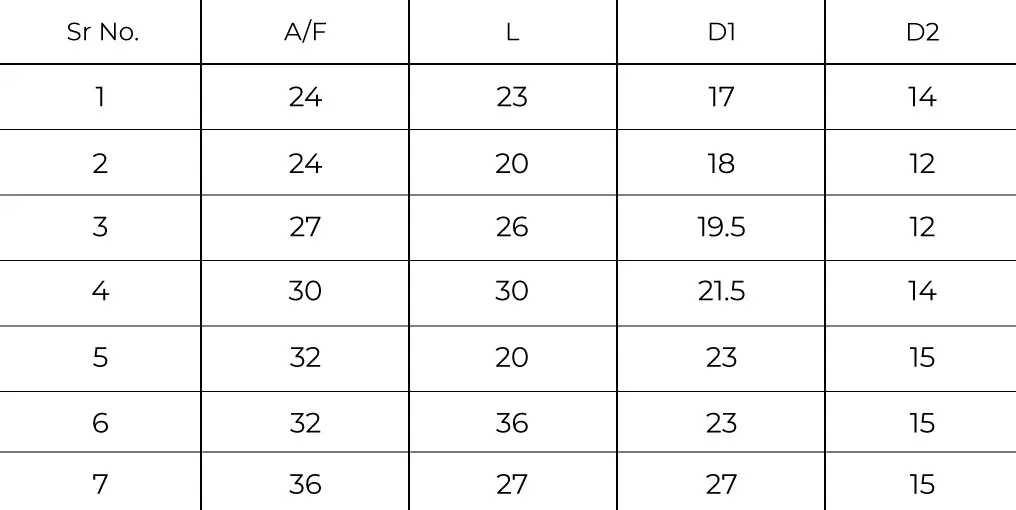

Similar to ferrules we also manufacture Nuts by the cold forging route. For Nuts we have limited options, our range starts from A/f 24mm to A/f 38mm only. As per the customer’s requirement we can modify its length and internal diameters. Following are the list of the sizes that we manufacture.