Machining

TRIA is the best choice for your machining needs.

We have high end machines of exclusive brands in our machining facility like Sliding Head Type CNC Automatic Lathe Machines.

With these high end machines, we can offer you the following:

Ease in machining SS304 / SS316 or any duplex stainless steel

Almost burr free parts

Machining of work pieces in diverse shapes and sizes

Rapid, smooth operation with minimal idle time

Machining since 1995

Our conventional setup of machines : Center lathes Horizontal milling machine, vertical milling machining, drilling, tapping, thread rolling, centerless grinding, cylindrical grinding, Automats, polygon turning machine, band saws etc.

Keeping up with the changing pace of technology

As an organization, we like to learn and keep ourselves up-to-date. Thus, we have invested in these modern set of machines: Cleaning machine, bundle cutting machine, vibrodeburring machine, marking machine. To add value we have ultra-sonic cleaning machine, TIG welding, forging setup and clean room for assemblies, heat treatment facility & few SPM’s (special purpose machinery).

Fully equipped to meet the customers’ requirements

- Good supplier network for surface treatment and allied machining needs

- Ability to select right materials based on customers’ requirements

- Our very own inspecting facility

- The right systems in place

Serving the following sectors

- Automotive

- Telecom

- Hydraulics

- Switchgears

- Waste management

- Construction equipment

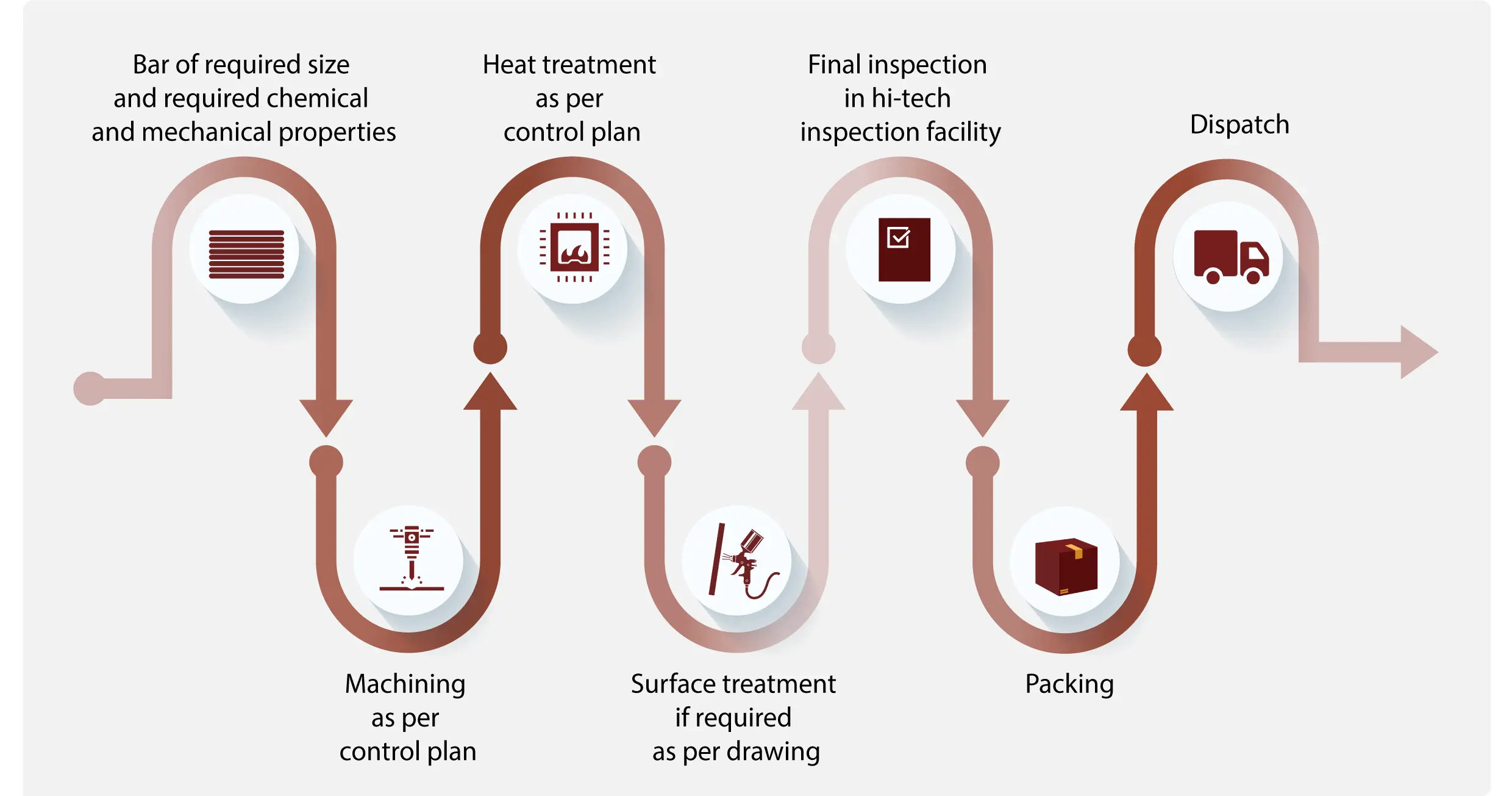

Bar Route Process

Manufacturing components by bar route process. Various operations like machining, heat treatment and surface treatment are done on the raw material in the form of a bar of required size and required chemical and mechanical properties. Final inspection of the component is carried out in our hi-tech facility having camera inspection, CMM, surface finish tester, etc. After this thorough inspection it is packed and dispatched.

Process

A fully audited, mature sourcing and production process to ensure you receive only the best quality in material and machining

Traceability

We track all raw material carefully through the production process

Collaboration

- Our team is uniquely capable of collaborating with you to understand your requirements

- Working with TRIA Group means trust. We are standing ready to work with you